How To Heat Set Speedball Fabric Ink?

Have you ever tried your hand at fabric printing only to be disappointed by the lack of longevity in your designs? If so, worry no more. In this article, we will explore the process of heat-setting Speedball fabric ink to ensure that your printed creations stand the test of time.

Whether you are a seasoned pro or a newbie to fabric printing, these simple steps will guide you toward vibrant and durable designs that won’t fade or wash away.

So grab your Speedball fabric ink and get ready to take your creativity to the next level!

How to Heat Set Speedball Fabric Ink

Heat setting Speedball fabric ink is an important step to ensure that the ink adheres properly to the fabric and remains durable after washing. Here’s how you can heat-set Speedball fabric ink:

Materials You’ll Need:

- Iron or heat press

- Parchment paper or a thin cotton cloth

- Fabric with the applied Speedball fabric ink design

Steps:

- Wait for Ink to Dry: After you’ve applied the Speedball fabric ink to your fabric, allow it to air dry for at least 24 hours before attempting to heat set it. This will ensure that the ink has had sufficient time to bond with the fabric.

- Prepare Iron or Heat Press: Set your iron to the appropriate temperature. Refer to the instructions provided by Speedball for recommended heat settings based on the fabric type you’re using. If you’re using a heat press, set it to the recommended temperature.

- Protective Layer: Place a clean piece of parchment paper or a thin cotton cloth on top of the fabric with the ink design. This layer will help protect the fabric and ink from direct contact with the iron’s or heat press’ surface, which could potentially cause scorching or damage.

- Heat Setting Process:

- Place the protective layer (parchment paper or cloth) over the inked design.

- Gently press down the heated iron or heat press onto the protective layer. Apply even pressure and hold the iron in place for the recommended amount of time. This time can vary depending on the fabric and ink type, so refer to Speedball’s instructions.

- Make sure to move the iron or heat press around slightly to avoid concentrating the heat in one spot for too long, which could lead to uneven heat setting.

- Cooling: After the recommended heat setting time has passed, carefully lift the iron or heat press and remove the protective layer. Allow the fabric to cool down completely. Cooling is essential to the process as it helps the ink fully bond with the fabric fibers.

- Wash Instructions: While Speedball fabric ink is heat set, it’s essential to follow proper care instructions for your fabric to maintain the longevity of the design. Usually, this involves washing the fabric inside out and using a gentle cycle in cold water. Avoid using harsh detergents or bleach, as they can impact the ink’s durability.

Remember, the specific instructions may vary based on the type of fabric you’re using and the particular Speedball fabric ink product. Always refer to the manufacturer’s guidelines and recommendations for the best results.

Heat Set Speedball Fabric Ink- Unique Methods

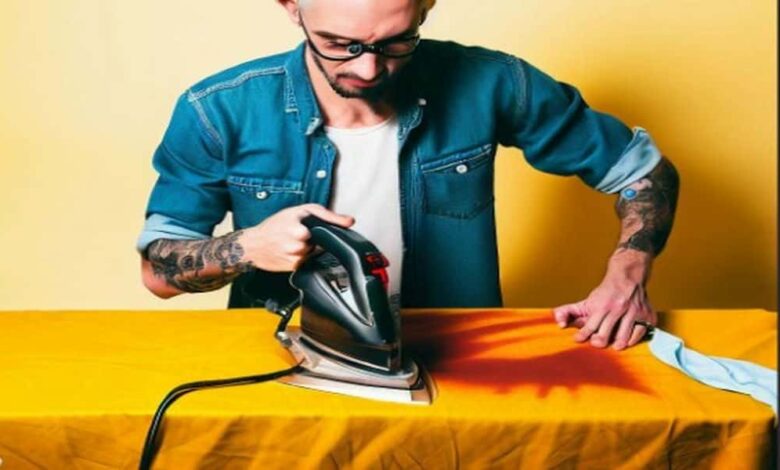

Iron Method

- Place a piece of parchment paper over the inked area.

- Preheat the iron to a medium setting without steam.

- Apply even pressure and iron over the parchment paper for 3-5 minutes.

- Pros: Convenient for small projects.

- Cons: May require multiple rounds for larger designs.

Oven Method

- Preheat the oven to 350°F (175°C).

- Place the fabric item on a baking sheet, inked side up.

- Bake for 4-5 minutes.

- Pros: Efficient for multiple items.

- Cons: Risk of scorching if not monitored.

Heat Press Method

- Preheat the heat press to 350°F (175°C).

- Position the fabric between the press plates.

- Close the press and hold for 20-30 seconds.

- Pros: Professional results.

- Cons: Expensive equipment.

Dryer Method

- Place the fabric item in a tumble dryer.

- Set to high heat and run for 40-50 minutes.

- Pros: Convenient for bulk items.

- Cons: Less precise control over heat.

Troubleshooting Common Issues When Heat Set Speedball Fabric Ink

Even when you follow all the guidelines meticulously, you may run into some hitches. Below are common problems that could arise during the heat setting process and how to resolve them:

Ink Smudging or Smearing

Issue:

The ink smudges during or after the heat-setting process.

Possible Causes:

- The ink was not completely dry before heat setting.

- Too much pressure or movement was applied during the ironing process.

Solution:

- Ensure the ink is completely dry before attempting to heat set. This typically takes about 24 hours.

- Use smooth strokes when using an iron to avoid disturbing the ink.

Color Fade or Dullness

Issue:

The color fades or turns dull after heat setting or washing.

Possible Causes:

- Insufficient heat during the setting process.

- Washing the fabric in hot water or using harsh detergents.

Solution:

- Re-heat set the item, increasing the temperature slightly and checking the manufacturer’s guidelines for maximum heat recommendations.

- Always wash the fabric in cold water and avoid using harsh detergents or bleach.

Inconsistent Texture

Issue:

The ink texture varies across the design, appearing patchy or uneven.

Possible Causes:

- Uneven heat application during the setting process.

- Uneven ink application before drying.

Solution:

- Ensure that you apply heat evenly across the design. For large designs, it may be necessary to heat set in sections to ensure uniform treatment.

- Consider reapplying ink in the patchy areas and going through the drying and heat setting process again.

Fabric Scorching or Damage

Issue:

The fabric appears scorched or damaged after heat setting.

Possible Causes:

- Excessive heat during heat setting.

- Fabric not suited for high heat.

Solution:

- Always refer to the manufacturer’s guidelines for the ink and fabric to ensure you’re not exceeding the recommended temperatures.

- Test a small, inconspicuous area of the fabric before heat setting the main design.

Adhesion Problems

Issue:

The ink doesn’t adhere well to the fabric, leading to peeling or flaking.

Possible Causes:

- Insufficient heat or time in the heat setting process.

- Fabric not pre-washed or containing sizing/oils.

Solution:

- Increase the heat setting time slightly, ensuring you’re within the manufacturer’s recommended guidelines.

- Pre-wash fabric to remove any sizing or oils that could inhibit ink adhesion.

By understanding and addressing these common issues, you can ensure that your projects turn out as intended. Remember, practice makes perfect, and making a few mistakes along the way is okay. The important part is learning how to fix them.

Tips for Longevity Speedball Fabric Ink

Maintaining the vibrancy and durability of your fabric designs involves a few key practices that go beyond just proper heat setting. Here are some tips to ensure that your Speedball fabric ink designs last as long as possible:

Washing Care

- Turn Inside Out: Before washing the fabric, turn it inside out to protect the design from direct abrasion against other clothes or the washing machine itself.

- Cold Wash: Use cold water settings for washing the fabric. Hot water can lead to fading or even partial removal of the ink.

- Gentle Detergents: Opt for mild detergents and avoid any that contain bleach or harsh chemicals, as these can degrade the ink over time.

- Hand Wash for Delicate Designs: If your design has intricate details or multiple colors, consider hand washing to preserve its integrity.

Drying

- Low Heat or Air Dry: Use a low heat setting on your dryer, or better yet, air dry the item to prevent the ink from cracking or fading. Excessive heat can undo some of the heat setting’s effects.

- Avoid Direct Sunlight: Keep the fabric away from direct sunlight while air drying to prevent UV rays from fading the colors.

Storage

- Flat Storage: Store flat or rolled to avoid creases that could crack the ink over time.

- Cool, Dry Place: Keep the fabric in a cool, dry place away from direct sunlight for long-term storage.

Regular Check-ups

- Inspect After Washing: After each wash, inspect the design for signs of wear and tear. Catching an issue early could allow for simple fixes like re-heat setting.

- Touch-Up When Necessary: If you notice fading or cracking, consider a touch-up with more ink followed by a re-heat setting (within the manufacturer’s guidelines).

By following these tips for longevity, you’re ensuring that your designs remain vibrant and intact for a longer time. Good maintenance practices make all the difference in extending the life of your fabric ink projects.

Wrap Up

Heat-setting Speedball fabric ink is essential to ensure the longevity and durability of your printed designs. Following the proper techniques and using the right tools can effectively bond the ink to your fabric, preventing it from fading or washing out.

Remember to use a heat press or iron set at the appropriate temperature for the type of fabric you are working with. Allow sufficient time for heat setting, and be careful not to move or disturb the fabric during this process.

With these tips in mind, you can confidently create vibrant and long-lasting designs on your fabric projects. So go ahead, give heat setting a try, and enjoy your beautifully printed creations!