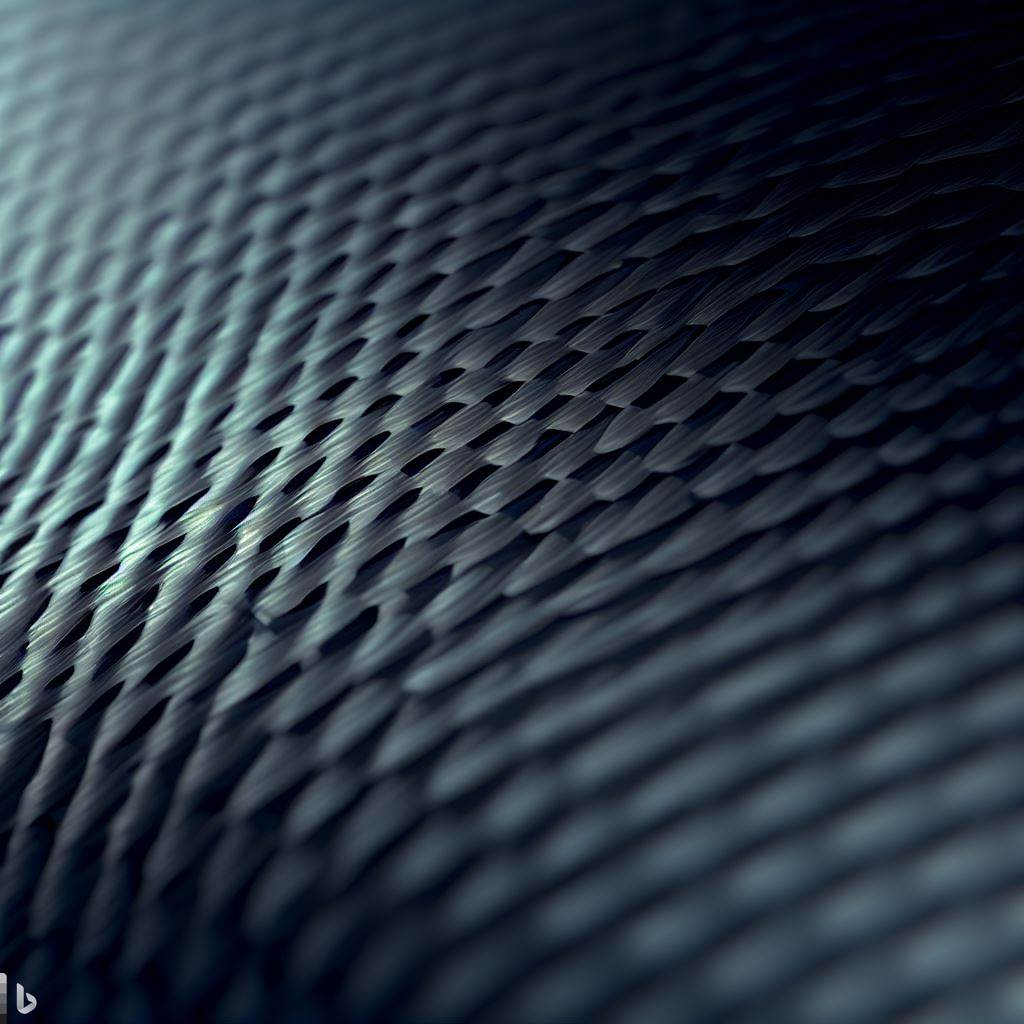

What exactly is nonwoven carbon fiber?

Carbon-based nonwoven fiber has a wide range of applications. Based on the requirements, they can be customized in various weaves and suit various purposes. Nonwoven carbon fiber is made by moulding thermosetting polymers such as polyacrylonitrile and rayon together. The control process is subjected to heat, strain, or carbonization treatment.

The nonwoven carbon fiber is known for its tear resistance property. This quality can help achieve your goal of using it for a long time. Depending on the strength required on the nozzle, different filament ratios are used. The more packed they are, the more durable the quality guarantee you will have on demand.

How is nonwoven carbon fiber made?

A water solution is applied to nonwoven carbon fibre sheets. All of the sheets on the board are placed in a binder. The nonwoven fabric is heated, and it dissolves in the metallic mould. The process will continue until they are in a position to shape it. the first step is almost coplete her.

The resin is then added to the mixture and heated to roughly 300 degrees Celsius. It will enable the breakdown and vaporisation of the binder components. The previously hidden side of air bubbles will now be visible on the fiber. Heat resistance is critical in this class for bagging the proper fiber on demand.

Carbon fiber nonwoven properties:

- Fiber Name: Carbon Fiber Composition

- Polymers of organic origin

- Breathability

- Yes, it is lightweight.

- Stretch Ability 1K, 3K, 6K, 12K, and 50K

- High heat retention abilities

- High susceptibility to bubbling

- Medium

- High-performance products such as aircraft, racecars, and sporting equipment frequently use this material.

Where are nonwoven carbon fibers used?

Nonwoven carbon fiber has sparked a new manufacturing revolution. They have made many things conceivable that we used to dismiss as pointless fantasies. There are some items whose prices will rise if they are not used. So, you should be thankful that we have carbon-based nonwoven fabric for our needs.

There are numerous applications for nonwoven carbon fiber. They are a fantastic choice for road and sea transport because they are both sturdy and lightweight. Their high strength also makes them an ideal companion for technological devices. It is also used in the production of cars and biomedical equipment.

What are the features of carbon fiber nonwoven?

The nonwoven carbon fiber ratio is an excellent example of superior strength. Despite its small weight, it is very difficult to force out of its shape. If you compare the strength to that of aluminum, it will win by a factor of two. Corrosion concerns will never rip off like steel, and you will be able to use it for a long time.

Heavy stress barriers can be simply removed. They are also non-flammable, providing complete fire protection. Nonwoven carbon fiber is also used in medical devices because it does not contain any hazardous substances. The low-maintenance property also contributes to its high market demand.

Related posts:

What exactly is TNT nonwoven fabric

How may non-woven fabric be recycled